Blog

11 Boilers Safety Tips Every Homeowner Should Know: a No-Nonsense Guide

Boilers work quietly, day in and day out, and most of the time, you don’t give them a second thought. And why would you?

They’re tucked away in the basement or a closet, a bit of unsung machinery doing its best to keep things warm. But here’s the thing: boilers are like that sturdy, no-fuss friendship that never complains but secretly needs periodical looking after to keep the spark alive.

As you’ll see in an anecdote below, reliable boiler repair services can mean the difference between a smoothly running winter and a costly disaster.

Here’s your no-nonsense guide to your boiler’s safety—simple yet key tips to prevent costly repairs or safety issues. Check out our boiler safety checklist below so you’re never left in the cold!

Schedule Regular Maintenance

The first rule of boiler care: get a professional boiler safety inspection once a year. This isn’t a suggestion; it’s the key to keeping your boiler running like a well-oiled machine. Annual maintenance is a chance for a technician to:

- Check for leaks or weak spots

- Measure and regulate pressure

- Clean internal components to prevent buildup

- Test safety features (we’ll get to these)

Skipping a boiler safety check-up might save you money in the short term, but a yearly inspection catches small issues before they turn into big (and expensive) problems. Think of it as buying peace of mind.

Anecdote, a Surprise for a First-Time Homeowner:

One homeowner thought they were in the clear, having bought a house with a boiler that had seen yearly services since 2014. But their first inspection uncovered a major issue the previous owner—and years of professional check-ups—had missed!

A copper pipe was used instead of plastic for the condensate, and acidic condensate had eaten it away, almost entirely disintegrating it. Regular inspections (or “PTOs”—Periodic Technical Overhauls) aren’t just routine—they’re a chance to catch details missed as far back as installation.

Keep the Area Around Your Boiler Clear

Your boiler needs space to breathe… figuratively. But also in real life! Keeping piled-up boxes, clothes, or anything flammable around it isn’t just clutter. It’s an invitation for things to go wrong in a way that’s inconvenient at best and horrifying at worst. Without proper ventilation, your boiler can start struggling, overheating, and even exploding with (again, figurative) rage.

- DO: Keep the area free of clutter and combustibles.

- DON’T: Treat it like a shelf. Nothing on top, nothing leaning against it.

Proper ventilation also keeps the air clean around the boiler, which helps it function better. So keep that space open and clear. Your boiler likes its breathing room.

Monitor Boiler Pressure Regularly

Your boiler’s pressure gauge isn’t just for show; it’s the boiler’s way of saying, “Everything’s steady,” or hollering at Houston… regarding a PROBLEM. Boilers generally operate between 1 and 2 bars. If the pressure strays from that, that’s your cue to pay attention.

- Low Pressure: This usually means there’s a leak or an issue with the system’s seal. If left unchecked, low pressure can lead to a boiler that struggles to heat—or, worse, gives up entirely when you need it most.

- High Pressure: This means trouble is brewing on the inside. The pressure can strain the boiler’s components, and trust us, they don’t respond well to that. Too much pressure is a recipe for expensive repairs—or worse, a full shutdown when you least expect it.

How to Check Pressure Safely:

Locate the pressure gauge (usually right on the front). Make it a habit to glance at it each month. If it’s creeping outside the normal range, do a quick check:

- DIY Tip for Low Pressure: If the pressure’s a bit low, you may be able to top it up using the filling loop (check the manual for your model). But if the gauge keeps dropping, don’t keep topping it up—call in a professional.

- High-Pressure Warning: For high pressure, don’t try to bleed it yourself. This is the boiler telling you it needs a pro. Call in a technician and avoid taking chances with excess pressure.

A monthly pressure check takes just a few seconds and saves you from a potential mid-winter shutdown. If that gauge shows anything out of the ordinary, better safe than sorry—get a technician to take a look.

Install Carbon Monoxide Detectors

Carbon monoxide (CO) is the stealthy villain of the gas world: colourless, odourless, and entirely lethal. If your boiler starts leaking CO, you’d never know—until it’s far too late. That’s why CO detectors are a must.

- Where to Place Them: Install one near your boiler and another near where people sleep. Think of it as an early warning system for the stuff nightmares are made of.

- Test Monthly: Give it a quick test each month to make sure it’s ready for action.

- Change Batteries Annually: Like clockwork, swap out the batteries every year. This is no time to gamble on a low-battery beep.

Why CO detectors matter:

- First Alert for Leaks: They’ll let you know before it’s too late.

- Cheap Insurance: Inexpensive but potentially life-saving.

- Peace of Mind: Sleep easy knowing this invisible threat isn’t lurking.

No one wants a horror story in their own home. A CO detector is your best defence against the quiet menace.

Familiarise Yourself with Boiler Safety Features

Modern boilers come with built-in safeguards, designed to keep things running drama-free. This helps with efficiency and aids in preventing many boilers safety hazards. Knowing these features is like having a cheat sheet for spotting trouble before it escalates:

- Pressure Relief Valve: This handy feature stops pressure from building up too high. When things get tense, it steps in to release the pressure—literally.

- Temperature Regulator: Keeps everything at a safe, steady temperature. If it’s doing its job, you won’t even notice it’s there.

- Safety Switches: These are designed to shut the boiler down if it detects unsafe conditions, preventing potential accidents. Think of them as the boiler’s own “no-go” buttons.

- Reset Button: If the boiler detects a problem, it’ll lock itself out to avoid further issues. But if you’re pressing this button more than once in a blue moon, the boiler’s sending you a message: call a professional.

Pro Tip:

During your annual boiler maintenance, have the technician show you these features and how they work. A quick run-through gives you peace of mind and helps you spot any early signs that need attention.

Ensure Proper Ventilation

Ventilation isn’t just a “nice-to-have” for boilers—it’s essential. Without proper airflow, your boiler can’t burn fuel fully, potentially leading to inefficient operation, carbon monoxide buildup, and increased wear on internal components. In short, a lack of ventilation is a fast track to trouble.

- DO: Clear any obstructions around vents or airflow paths—including dust buildup.

- DON’T: Block the intake or exhaust pipes (often outside). These pipes are essential for safely releasing combustion gases.

Keeping the area ventilated helps your boiler operate efficiently and cleanly, extending its lifespan and keeping your home safer.

Educate Household Members on Basic Safety

Boilers aren’t selective about who happens to be nearby when they decide to act up. So it’s worth educating the whole household on the essentials of boiler safety. Here’s a quick guide to getting everyone—from the kids to the house sitter—up to speed:

- Kids: Teach them that any strange clanks, hisses, or bangs are not the house “settling.” No, those are the sounds of a boiler asking for attention. And no, they are not supposed to be ignored.

- Partners and Roommates: Show them the emergency shut-off switch. They may never need it, but if something goes wrong, you’ll want them to know it’s there for more than decoration.

- House Sitters and Visiting In-Laws: Brief them on when to call a pro if things go sideways. If the boiler starts making noises like a haunted Victorian, they’ll know it’s not a feature but a problem.

In short, even if you’re the household’s Chief Boiler Operator, make sure everyone knows the basics.

Which Noises Are Unusual Anyway?

Boilers are generally quiet workers. But if you start hearing noises, it’s time to pay attention. Here’s what common sounds mean:

- Clanking or Banging: Often due to trapped air in the pipes.

- Hissing or Whistling: This could indicate a buildup of minerals or debris.

- Gurgling: This may signal low water pressure or the need to bleed the radiators.

While not every sound means disaster, unusual noises often indicate that your boiler’s asking for help. Addressing these issues early can prevent expensive repairs later.

Maintain Water Quality

In areas with hard water, minerals can build up in your boiler, affecting efficiency and potentially causing overheating. This isn’t just about being fussy—it’s about keeping your boiler in prime shape.

Consider:

A water treatment solution or regular descaling if you live in a hard-water area. Over time, this small step can prevent major problems.

Maintenance Tip:

During your annual service, ask your technician to check for signs of limescale and suggest water treatment options if needed.

*Limescale is a hard, chalky residue from mineral-rich (hard) water that builds up inside your boiler. It coats parts like the heat exchanger, reducing efficiency, causing overheating, and leading to costly repairs if left unchecked.

Know When to Call a Professional

Let’s be clear: boilers are not DIY-friendly machines. Some tasks—especially those involving gas or electricity—are firmly in “call a professional” territory. Sure, minor maintenance is fine, but anything beyond that? Let the experts handle it.

Here’s when you need a gas-safe engineer:

- Gas Smell: This is an all-hands-on-deck situation. If you smell gas, get everyone out of the house, avoid using electrical devices, and call emergency services immediately. This is a non-negotiable “pro-only” job.

- Pressure Problems: If your boiler’s pressure fluctuates constantly, don’t keep topping it up yourself. Frequent pressure drops or spikes can mean deeper issues, and it’s time for an inspection.

- Pilot Light Troubles: Consistent problems with the pilot light could signal issues with the gas supply or burner. A professional can diagnose it safely and prevent bigger, costlier issues down the line.

And remember: while unclogging a sink or fixing a leaky faucet might be manageable DIYs, anything involving your boiler’s gas or internal components is best left to the pros. This isn’t the time to test your inner handyman.

Protect Against Frozen Pipes

When temperatures drop, your boiler’s water pipes can freeze, blocking the water supply and leading to bursts. To prevent this:

- Keep your thermostat at a low but steady level when you’re away.

- Insulate exposed pipes, especially those in unheated areas.

- Open cabinet doors near pipes to let warm air circulate.

Anecdote:

One new homeowner thought they were energy-efficient by running their new heat pump and keeping the boiler’s thermostat low. All went well—until a cold snap hit. With the boiler barely running, the water in the radiators froze. When the pipes expanded, one burst in an awkward, hidden spot. The result? A hefty $4,000 repair bill.

Their (lousy, if we may say so ourselves) contractors hadn’t warned them. A common boilers’ safety issue: dual heating setup can lead to freezing if the boiler isn’t kept warm enough to keep the lines flowing.

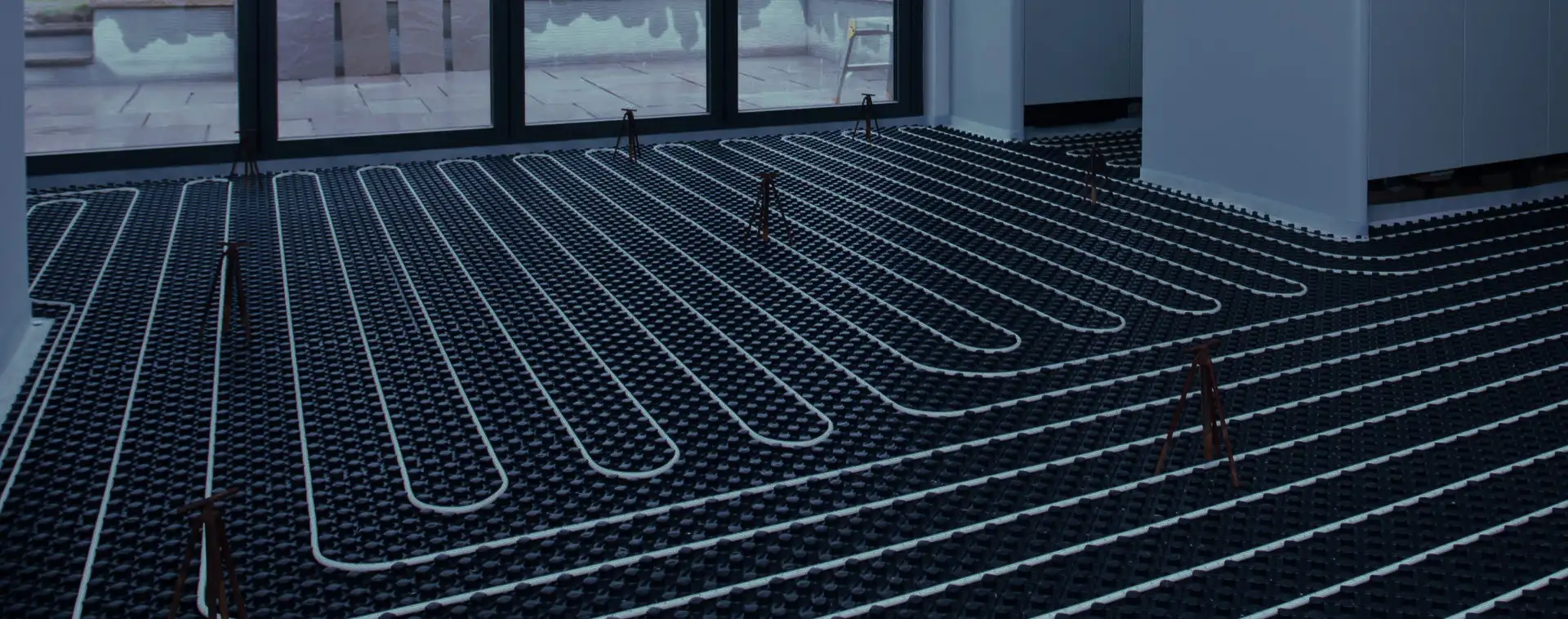

Whether you're installing, repairing, or servicing your radiant floor heating system in San Francisco contact Ros Plumbing today.